why do starter batteries commonly fail?

Capacity fade is the most common cause of failure that often goes unnoticed. An engine may still crank well at 30%; however, going lower in capacity is subject to no-start, especially on low charge and when cold.

A CCA test alone does not provide conclusive results, nor can BMS predict capacity of a starter battery.

Core Features

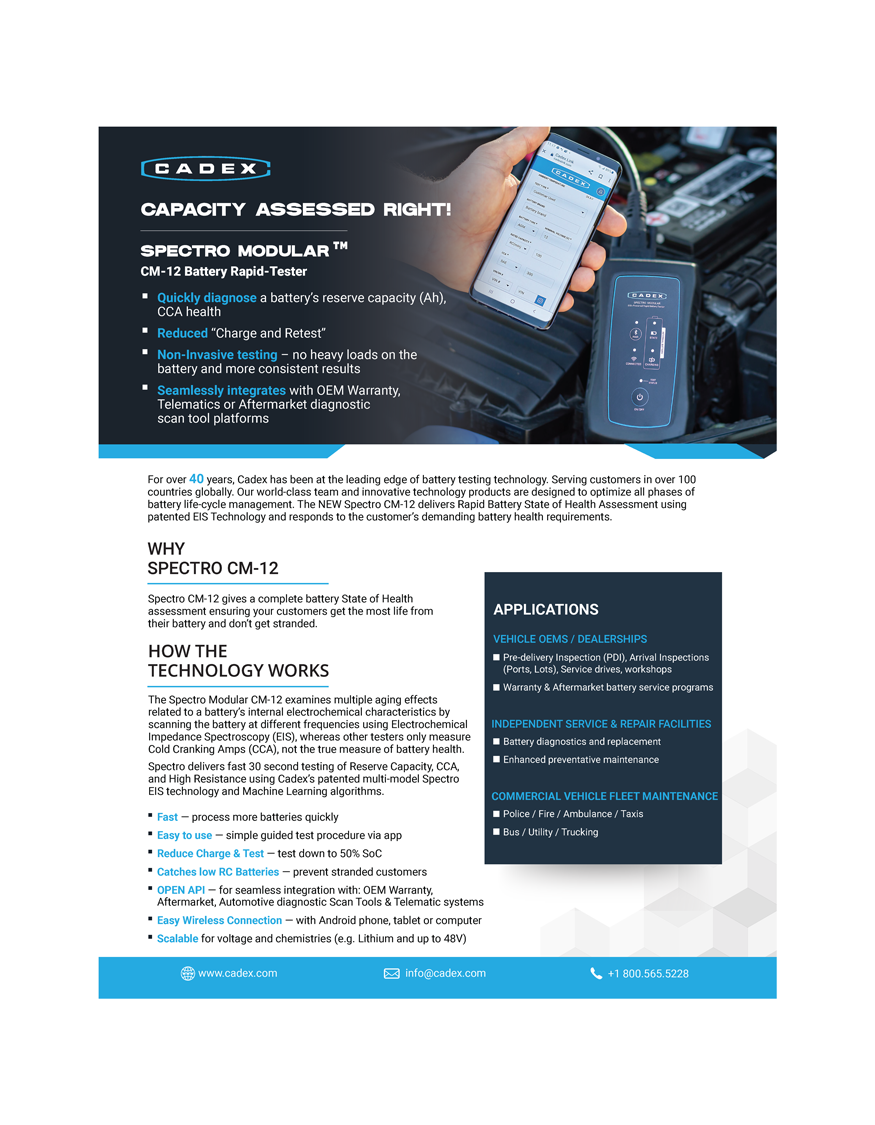

Spectro Modular

Fast - process more batteries quickly

Easy to use - simple guided test procedure via app

Reduce Charge & Test - test down to 50% SoC

Catches low RC batteries - prevent stranded customers

OPEN API - for seamless integration with: OEM Warranty, Aftermarket, Automotive diagnostic Scan Tools & Telematic systems

Easy Wireless Connection - with Android phone, tablet or computer

Scalable for voltage and chemistries (e.g. Lithium and up to 48V)

CM-12: Services regular starter batteries, 12V; 35-120 Ah with generic matrix

CM-48: Services heavy duty starter batteries, 12-48V; 35-300 Ah with X-Matrix

Services lead acid and Li-ion architecture

Additional Features

Rapid Capacity Tester

- Non-invasive. Unit stays cool during test

- Test time is 30 seconds. Longer with large batteries

- Tests battery down to 50% state-of-charge

- Easy wireless connection with Android phone and PC

- Matrices for deep-cycle and lithium batteries on request

- Communication to host and cloud

- Compact size and ease of use

Applications

Spectro Auto

Superior Speed and Customer Service

An OEM dealer in Florida leveraged the Cadex Spectro device to great success, improving customer service speed and satisfaction. On peak days, they averaged several hundred in-bound dealer service touch points with clients.

The Spectro device enabled them to streamline their service experience--battery state of health was fully diagnosed for vehicle cranking and reserve capacity including remaining useful life upon intake. This ensured customers got the most life from their battery and faulty batteries were detected before being stranded.

Time saved and faster maintenance turnaround |

|

Increase Brand Quality Scores (IQS) |

|

Retain brand loyalty; customer satisfaction |

|

First to bring starter battery capacity assessment capability to North America's commercial OEM sector |

Spectro™ assesses capacity to estimate the remaining useful life of batteries.

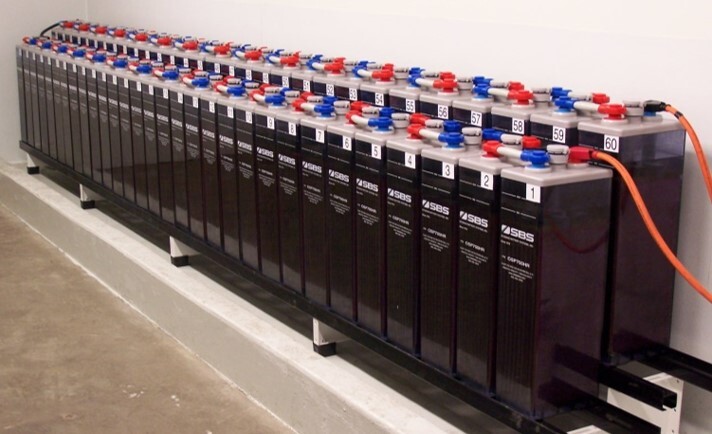

Spectro Monitor

Observe of Battery Health in Field Installations

Spectro Monitor is the only technology capable of reading battery capacity non-invasively. As capacity fade is the most common failure mode, Cloud Analytics calls for replacement when the capacity drops below the user-set threshold.

Spectro Monitor requires a model-specific matrix that Cadex provides by scanning aged batteries of the same model. Applications are UPS and BESS with lead acid and lithium systems up to 48V nominal and 300 Ah.

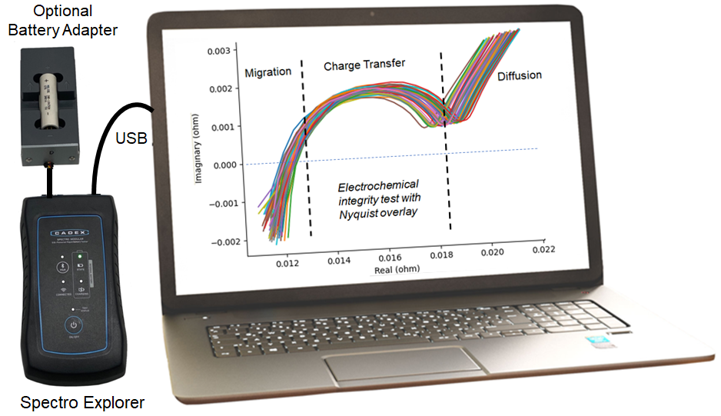

Nyquist plot discloses information relating to battery capacity, derived by AI.

Spectro BMS

Assessing Capacity by EIS

Spectro BMS assesses battery capacity by EIS, a technology that improves accuracies over coulomb counting. The EIS Direct Drive enables testing larger batteries with low frequency on a compact circuit that incorporates in existing BMS circuits. Test accuracy hinges on the maturity of the matrix. Applications are EVs, UPS, and BESS.

- Current draw during test is 500 mA

- Test time 30 second test; longer with larger batteries

- Frequency scan 2,000 Hz to 0.1 Hz

- Internal battery resistance must be above 500 µΩ

Overlaid Nyquist plots of 100x 18650 cells

Spectro Explorer

A Snapshot of Battery Health

Spectro Explorer captures the electrochemical evidence of a battery in 30 seconds. The derived Nyquist plots display anomalies, such as low capacity and dendrite growth. The system supports lithium and lead based packs.

- The Spectro Explorer tests Li-ion and lead acid batteries from 3−48V.

- A frequency scan from 2,000−4Hz produces the Nyquist plot shown.

- The Spectro Explorer serves battery manufacturing in QA, acceptance testing, and integrity checking for safety of batteries in micro-mobility.

- Spectro assesses battery capacity with frequency scan from 2,000 Hertz to 4 Hertz (and lower)

- Scan assesses battery performance and requests replacement when low

- A 'pass' gives a grace period to next service; a 'fail' requires immediate replacement

- Internal battery enables 250 tests between charges and stores 1,000 test results

- Communication to host is by Bluetooth or USB; cloud connectivity is by Wi-Fi

- 1 meter (40") test cable; USB recharges internal battery

- D: 182mm (7.16“); W: 96mm (3.78“); H: 47mm (1.85“).430g net (0.94 lb.). comes in transit case

| Models | V Range | Ah | RC | CCA | Frequency | Test Time |

|---|---|---|---|---|---|---|

| CM-12 | 3-12V nominal | 35-150Ah | 84-360 | 1200A | 16-2000Hz | 30-45 sec |

| CM-48 | 3-48V nominal | 35-300Ah | 84-720 | 2000A | 0.1-2000Hz | 30-180 sec |

Environmental

- Temperature: -10℃ to +45℃ (14°F to 113°F) Humidity: 10–80%

- Complies with CSA/UL/CE. RoHS. REACH, RED,WEEE, ISTA 3A, IP52 and FCC Type A

- Warranty against defective materials and workmanship is two (2) years from the purchase date;

the cable and clamps carry a one (1) year warranty.

* Battery must have 500µΩ or more of resistance

ㅤㅤ